24x7 Risk Monitoring Service

Your Next-Gen Control Tower

Decklar’s 24×7 Risk Monitoring Service turns visibility into execution. Powered by RADAR, it blends self-learning AI with human insight to detect, prioritize, and act on critical risks—scaling effortlessly from hundred to more than a hundred thousand shipments daily.

Why Manual Monitoring Fails in Complex Supply Chains

Monitoring thousands of shipments across borders, modes, and SLAs is impossible without automation. Traditional control towers track but often lack real-time risk prevention and autonomous action. Enterprises face mounting pressure to achieve end-to-end visibility, rapid decisions, and operational resilience.

Key Limitations

Overwhelming alert volumes flood teams with noise (e.g., 2,000+ monthly alerts)

Static SOPs can’t adapt to dynamic risk environments

Limited collaboration across partners and supplier tiers

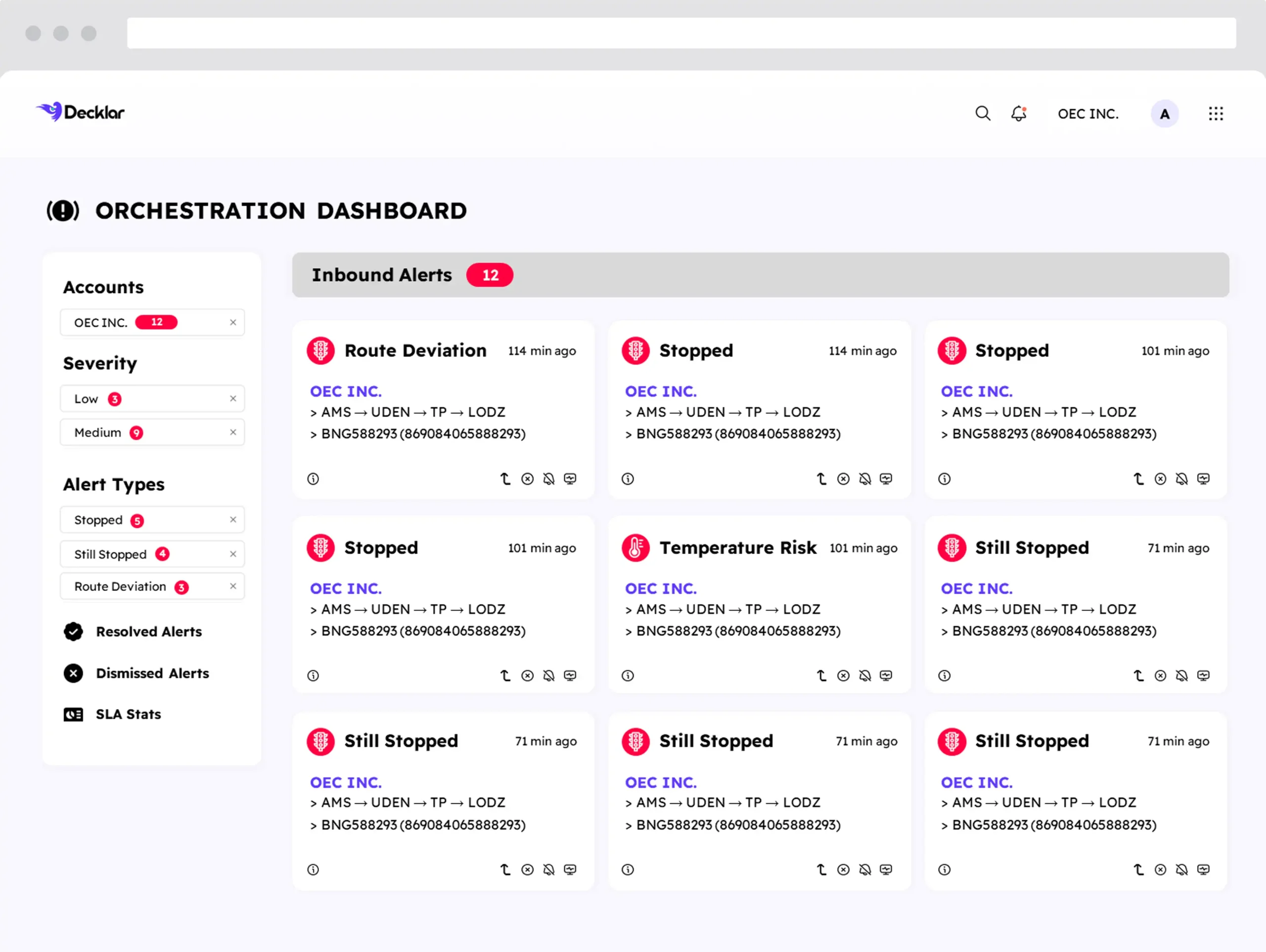

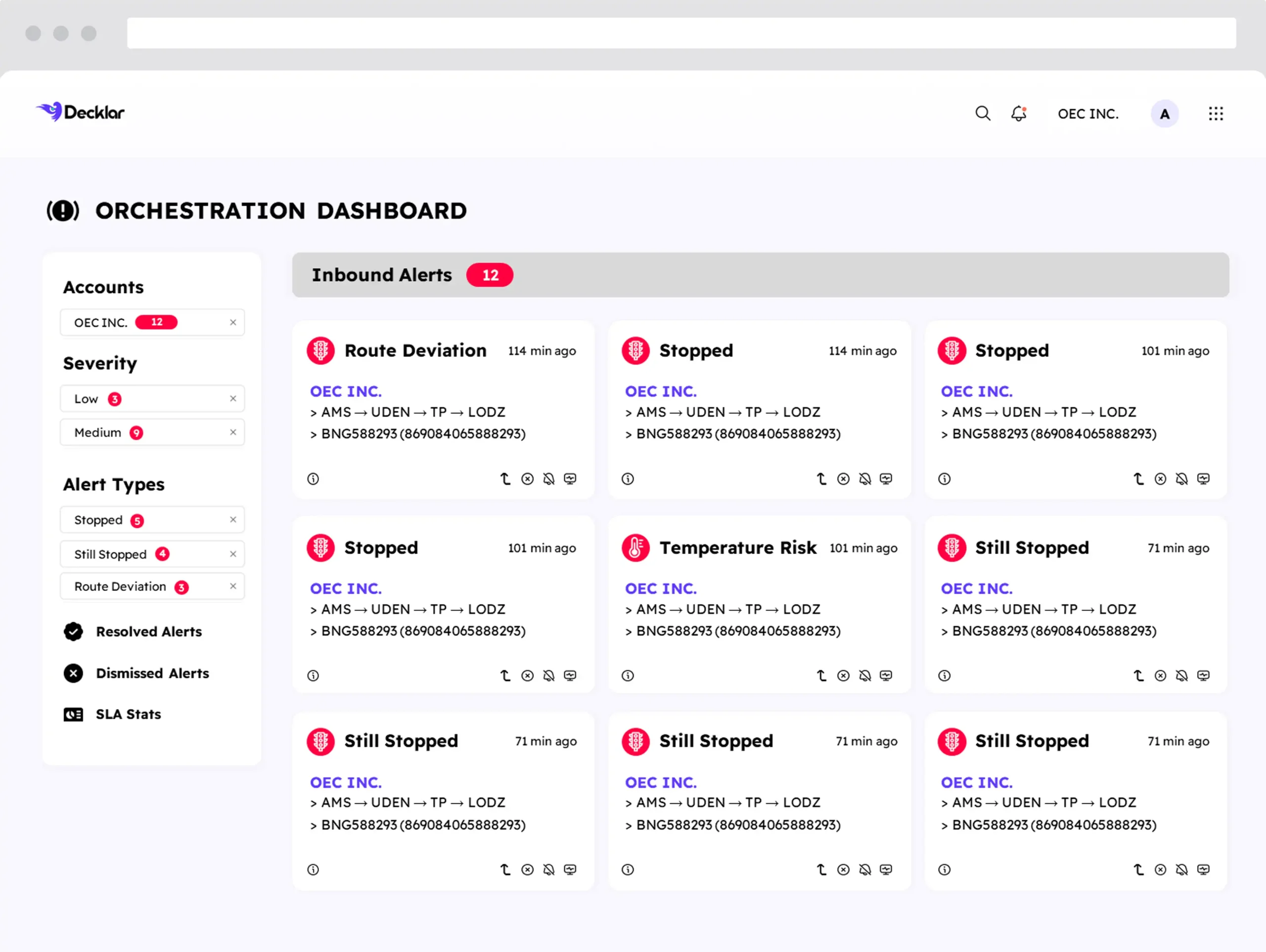

24x7 Risk Monitoring: The Decklar Way

Built on the RADAR platform, it blends real-time visibility signals, Decision AI, and human expertise for effective orchestration.

Key Features

Digital twin connects data across systems for unified visibility.

AI agents detect, filter, and prioritize risks automatically.

Our LogTech Engineers oversee human-in-the-loop decisions.

Integrates seamlessly with ERP, TMS, WMS, and visibility tools.

How It Works

From Noise to Precision

Real-Time Detection

AI scans shipment signals from devices, carriers, and documents to identify early indicators of disruption.

Intelligent Escalation

Filters out over 90% of false positives. Only flags risks with SLA-critical impact using predictive scoring.

Assisted Orchestration

Give your operations team a co-pilot that rewrites the orchestration playbook, live!

RADAR

The AI Engine Behind 24x7 Monitoring

- Predictive alerts

- Autonomous execution

- AI + Human-in-the-loop decisioning

- Predictive alerts

- Autonomous execution

- AI + Human-in-the-loop decisioning

24x7 Risk Monitoring Powered by RADAR

With or Without a Control Tower

| Risk Category | How AI Interprets Risk | Example Scenario |

|---|---|---|

| Detects GPS spoofing and lane-level anomalies | Vehicle exits route during off-hours in theft-prone zone | |

| ETA models factor in weather, transporter history, and real-time congestion | Delay triggered by known bottleneck at depot | |

| Sensor fusion (ambient light + location) for tamper pattern detection | Door opens in motion or outside geofenced boundary | |

| Filters out safe micro-spikes that don’t affect MKT | 2°C rise detected but safely within thermal profile | |

| Flags signal decay or battery drops before tracker stops communicating | Warns about shipment entering a blind spot | |

| Monitors delivery patterns and SOP adherence per carrier | Missed deliveries or extended dwell at cross-dock | |

| Flags high-value loads in high-risk zones for proactive observation | Black Friday electronics flagged for closer monitoring | |

| Forecasts risk from customs bottlenecks and handling patterns | 3-day delay predicted at Port of Discharge |

Building a Next-Gen Logistics Control Tower? Learn How RADAR Can Help.

Proven Outcomes Across Industries

Pharma & Life Sciences

92% alert noise reduction, 99% product release compliance.

Electronics

$1.2M saved per year by flagging high-risk shipments.

CPG

70% drop in repeat delays on lanes within 3 weeks.

Food & Beverages

$16M+ saved per G2000 with quality risk scenario planning by lane.

Decklar Delivers Results

10-20%

Cost reduction

20-40%

Fewer risk events

Up to 26%

Improvement in OTIF deliveries

54%

Fewer "Where is my order?" escalations